Vacuum extrusion technology

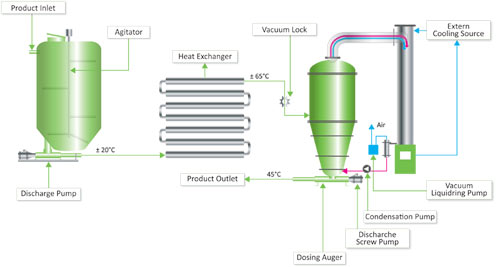

First, the substrate is heated up to a minimum temperature of 65°C. Then, the warmed biomass is pushed against a vacuum lock, with a pressure of 2-3 bars, so it enters the special vacuum vessel.

At the entrance of the vacuum vessel, the biomass disintegrates instantaneously because of the difference in pressure, by which part of the biomass is vaporized. This vapour condenses and collects at the bottom of the vacuum vessel, where the discharge pump transports it to a temporary storage tank or the fermenter. Because of the condensation of the vapour, the temperature of the biomass is lowered automatically to approximately 40°C, the desired temperature for mesophilic fermentation.

The effect of the pressure difference between the 2-3 bar before the vacuum lock, and the 0 bar (almost vacuum) inside the vacuum vessel, is in practice much larger than the 3-4 bar resulting from the simple comparison.

Under (almost) vacuum conditions, water already boils at temperatures around 45°C. Because the biomass enters the vacuum vessel at a temperature of about 65°C, it thereby receives an extra clout. The effective difference in pressure to which the biomass is exposed, therefby approaches approximately 5-7 bars.

Because of this brute effect, the biomass is opened up to at a macromolecular level. The enzymes and bacteria, which play a role during the hydrolysis phase, are allowed to do their job more efficiently this way.