Higher ethanol yields at a lower investment costs

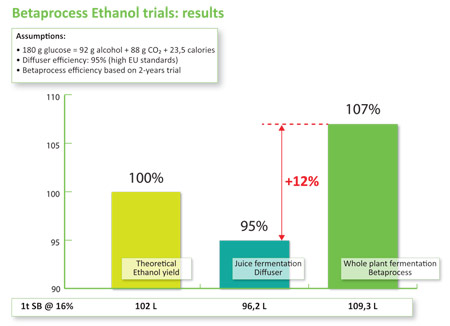

Research realised on behalf of Syngenta Crop Protection AG has shown that ethanol production facilities equipped with Betaprocess generate up to 12% higher ethanol yields over conventional plants. With current juice fermentation diffusors it is possible to achieve average efficiencies up to 95% of the theoretical yield, generating 96,2 litres of ethanol for each ton of sugar beet (at 16% suger content). Through Betaprocess an efficiency of 107% of the theoretical yield can be achieved, generating 109,3 litres of ethanol. This means an increase of over 13 litres of ethanol for each ton of sugar beet, accounting for 12%. This is a result of the cell disruption effect, which makes additional components to come available for fermentation, as well as the brute mechanical action on macromolecule level, resulting in smaller particles and more digestible saccharides

Total investements in new ethanol production plants can be reduced by 10-20%, due to Betaprocess. In general it is only possible to distil sugar beet juice, which makes it necessary to invest heavily in equipment needed for preparation and separation. Betaprocess however, makes it possible to distil the whole plant itself.

We provide turnkey installations comprising besides the Betaprocess unit, modified fermentation tanks and distillation columns, specifically designed for whole plant fermentation. Actually, Betaprocess pays for itself in this case.

Other additional advantages of Betaprocess are a much more stable production process with less failure and considerable savings on enzymes.